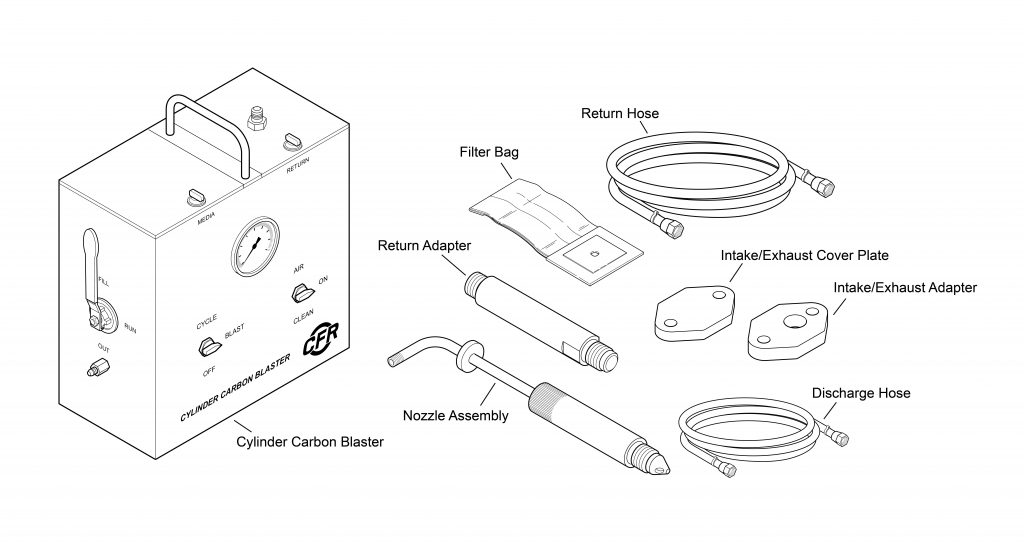

Cylinder Carbon Blaster

CFR Engines Inc. released a new design of its commonly used Cylinder Carbon Blaster with more robust construction and improved material handling for increased octane combustion chamber cleaning efficiency and reliability. Users can easily maximize the operating life of their cylinders and extend the period between mechanical top-end overhauls with regular cleanings using the CFR Cylinder Carbon Blaster.

Cleaning and regular maintenance reduces damaging deposits and build-up, restore temperature tuning ranges, and reduce downtime and cost of premature overhauls. Low mixture temperatures (MON) or low intake air temperatures (RON) will dictate when cylinder carbon blasting should be done. Effective carbon blasting addresses the combustion chamber, as well as the valve ports. Cleaning with the CFR Cylinder Carbon Blaster can be done with the cylinder remaining in place on the engine.

Download Brochure

View on CFR Website